Maintenance of machines and equipment

- Home page

- Our services

- Maintenance of machines and equipment

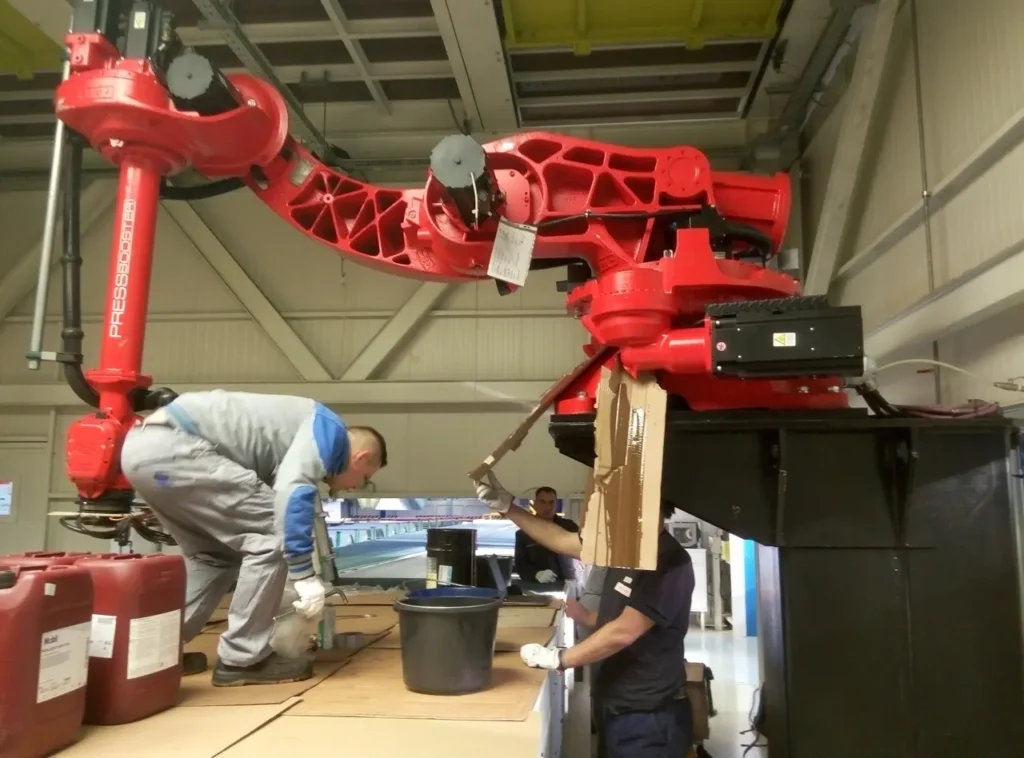

Maintenance of machines and equipment

To avoid unnecessary downtime in production, extend the life of your equipment, increase the productivity – these are the main reasons why we developed and standardized the concept of maintenance of industrial plants.

Our maintenance services are optimally adapted to your needs and production processes in your company.

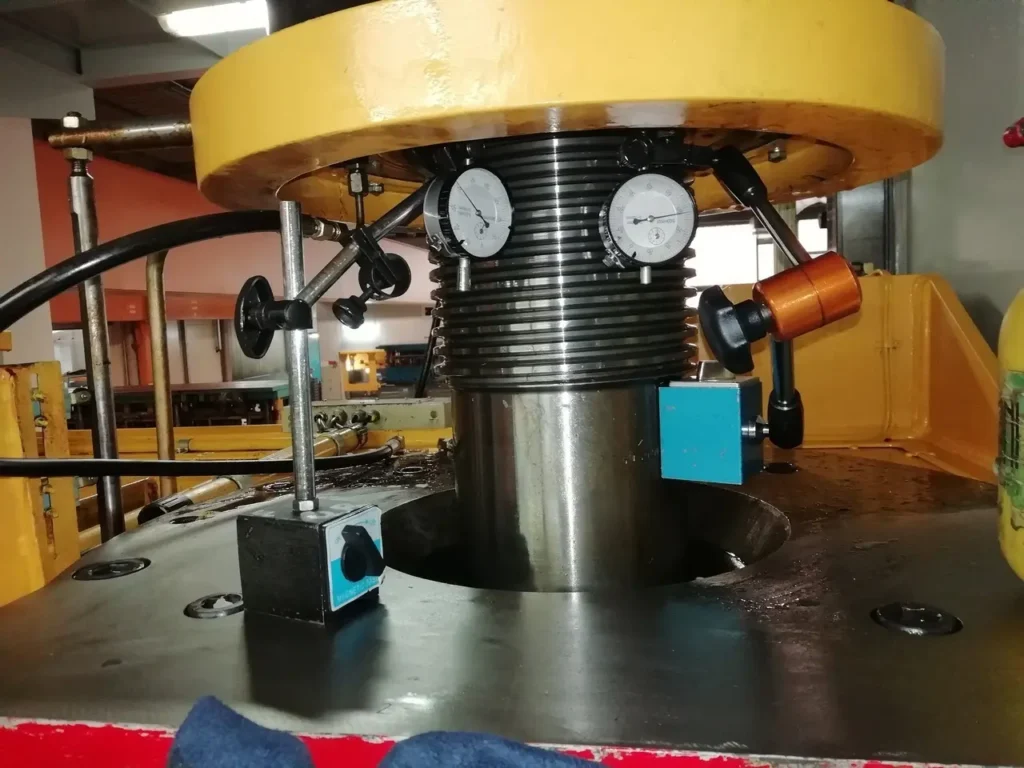

Preventive maintenance contracts:

Regular maintenance of your machines guarantee maximum productivity and reliability in the production process. Our preventive maintenance contracts offer you numerous advantages.

Our engineering team prepares and defines checklists in detail according to the specifics of your needs for each predefined periodical inspection.

After the inspection, your technical service receives a document on the preventive measures taken and possible suggestions for further preventive/planned activities.

Breakdown maintenance:

For customers who use our preventive maintenance contracts, we have special benefits for emergency interventions in case of breakdowns and production stoppages. Upon your invitation, the arrival at the plant and the intervention of our trained staff will follow and the restarting of the production in the shortest possible time.

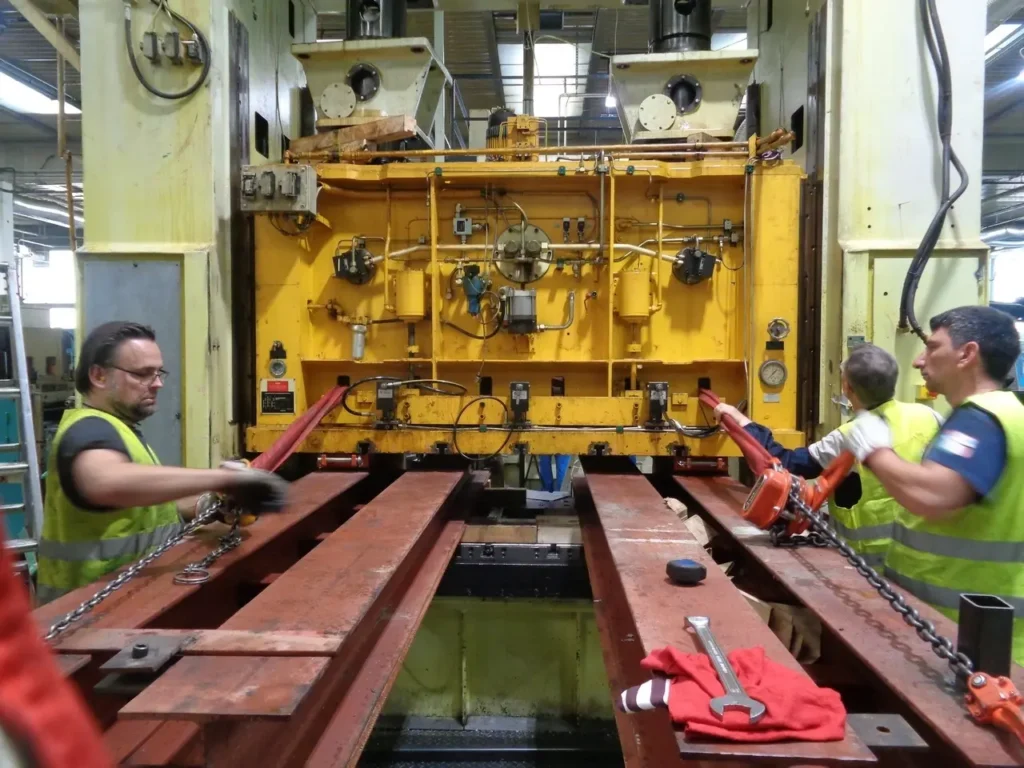

Scheduled maintenance contracts:

As a result of quality preventive maintenance, there are frequent requests from our clients for optimization and improvements of production equipment (retrofit).

Obsolete machines and lines can get significant benefit from modernization and adjustment that will increase their productivity and results so much so they can reach the performance of the new lines.

We are capable to support our clients throug the entire reconstruction process, starting from the feasibility study proposal, to complete realization.

Your advantages:

- Transparent and flexible service maintenance contracts

- The possibility of planning periodic inspections and implementing a plan of preventive measures

- The possibility of planning maintenance costs

- Reduced costs for engagement of service technicians

- Reducing the risk of production downtime

- Extending the life of your equipment

- Increasing productivity

- Priority response of our service technicians in case of breakdowns and production stoppages

- Obtaining a document about taken preventive measures

Other services

Maintenance of machines and equipment

Installation of Machines & Plants

(dis)Assembly of machines and plants

Industrial / robotic automation and solutions